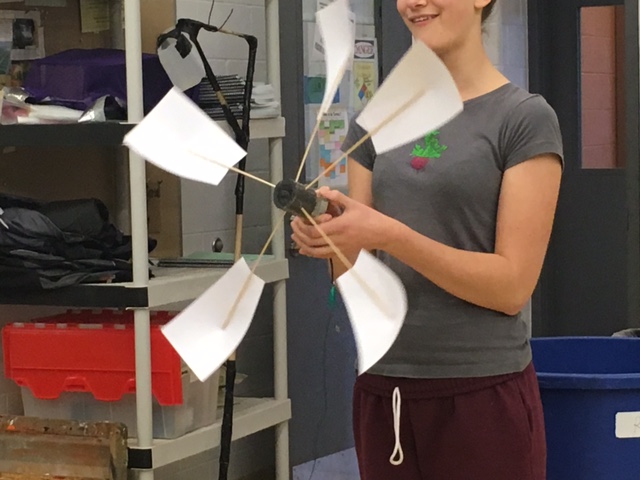

Excellent workmanship and attention to detail. However, when tested with the fan, it failed to rotate, lacking sufficient power to overcome the friction in the motor. Needs much larger/longer blades, since power available from the wind is proportional to swept area.

which was conceptual only; it would not turn, and which was not tested for functionality.

This larger version used CD cases to catch the wind. It was not tested. However, unit would likely catch the wind in both directions, so would not turn.

This turbine turned a little bit; however, the blades would not hold a fixed angle. The student did not appear to understand why the blade angle mattered.

I suggested that the blades be taped to better hold the correct angle.

This group worked on their large rotor, attempting to construct a post to hold the system.

Another group had previous built this rotor using cup-shaped blades:

Although this previous version would not turn, they spent the period making metal versions of the cup-shaped blades for their final version:

In the new version(above), they have eliminated the bearing entirely, so that there is no possible way for the turbine blades to rotate.

I pointed out that the turbine system is really 3 different subsystems:

- The wind turbine blade system itself

- The motor and gearbox system

- the tower

Each of these contains very different technical issues, which has tended to lead each design team in several different directions at once.

To make this challenge more effective and achievable, one could:

- provide the tower and gearbox system to the students, and limit the design or

- assign different teams to different problems.

In this design challenge, students built various prototypes, which in most cases were not tested for functionality. Nor did the class hold a design reviews to get feedback.

In most school-based design challenges, students are provided with a standard menu of materials. In this case, there was no standardization; every design used very different materials.

For the turbine portion of the design, Kidwind( the most common windpower educational system), has students methodically determine the optimum blade angle, length, and number. This was not done in this case, so the students had no empirical basis for the design of their turbine.

For the motor and gearbox portion of the challenge, students had been given no introductory experiences assembling Lego gear systems. They did not appear to understand the difference between gearing up or gearing down, the trade-off between speed and torque, or the frictional effects of long gear trains. Students also seemed confused by the concept of bearings, as being devices which restrict motion to a single axis.

For the tower system, again, different groups used very different materials. No prototypes were constructed of the towers; the full-size tower was the only unit constructed. All towers were different heights; some used PVC pipe, others a cardboard tube, another a hand-built cardboard box, another a wooden stick, another just held the motor in their hand.

No comments:

Post a Comment