The 201's gave short update presentations today:

Aquaponics tank group-

They have finished paneling one long side and one short side of the main tank. They used up the Gorilla Glue and are now uing other adhesive. Next week they need to work with Carpentry to cut up more pallets into pieces, then plan to coat everything in polyurethane.

Aquaponics plants group-

They have transplanted a number of plants, and started new ones. The fine mesh screen on the drain has been clogging up with clay fragments, so they are making a coarser screen using coarser mesh.

They also rearranged the tank room and diss-assembled shelving.

Next steps will include an auto grow-bed.

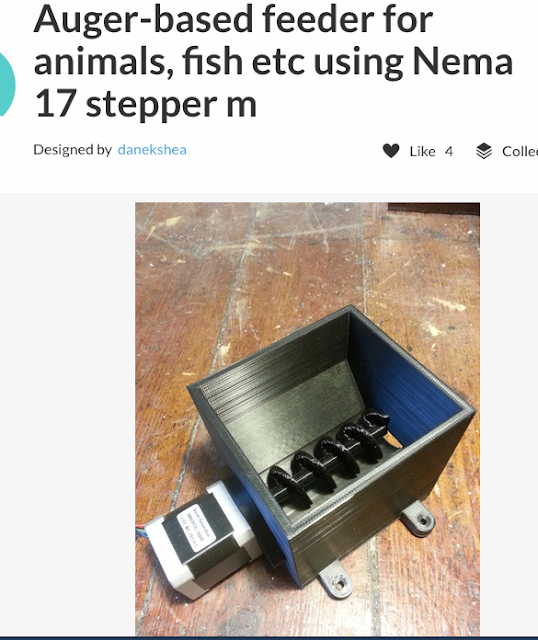

Fish Feeder(Spencer)-

Spencer is finishing up the revised fish feeder mechanism, which uses a screw auger:

Plastics-

Toby demonstrated his new and improved penny-board.

Mr. P-

Margaret Ford from Students for a Greener World( http://sgw.greennewton.org/ ) was here last week. She would like Green Engineering to present at the Newton Library on May 22nd @ 7 PM.

Each group should make a short video about their project both for the presentation and for the website.

Decide what topics go in, show the team and the prototypes.

Discussed what makes a documentary video- A- roll(interview)+ B-roll (action shots)

https://blog.pond5.com/8324-a-roll-and-b-roll-the-two-types-of-footage-you-need-to-tell-a-great-story/

Friday, March 31, 2017

Thursday, March 30, 2017

March 30th- 201's

Spencer made a lot of progress designing an improved fish feeder using the 3D-printed auger:

Version One used a modified section of PVC pipe:

Both versions were effective at moving the fish pellets.

Meanwhile the rest of the team rearranged the aquaponics system to get more room:

...while the soap team is cranking out soap bars for the upcoming Cambridge Science Festival:

For Friday: Presentations. Begin work on a short video presentation for Green Newton, funders, etc.

https://blog.pond5.com/8324-a-roll-and-b-roll-the-two-types-of-footage-you-need-to-tell-a-great-story/

Version One used a modified section of PVC pipe:

Iteration #2 Used copper sheet metal:

Both versions were effective at moving the fish pellets.

Meanwhile the rest of the team rearranged the aquaponics system to get more room:

...while the soap team is cranking out soap bars for the upcoming Cambridge Science Festival:

For Friday: Presentations. Begin work on a short video presentation for Green Newton, funders, etc.

https://blog.pond5.com/8324-a-roll-and-b-roll-the-two-types-of-footage-you-need-to-tell-a-great-story/

Example: The Magic of Making at MIT https://youtu.be/fQL7eArB4Qo

Monday, March 27, 2017

March 27th- Xplorers- Plastic Recycling

Up-cycling With Plastic!!!

Your task is to use HDPE and LDPE to build a product. You

will be up-cycling, which means that your product needs to have more value in

it’s final state. You must be creative, and think about what products will

benefit from the properties of the reworked plastic. The best projects will

look like something that you would actually buy in a store.

Day 1

|

Day 2

|

Day 3

|

Day 4

|

Questions 1 – 3:

Research and design your product

|

Questions 3 - 4:

Design and build prototype

|

Question 5:

Design Review

|

Build product and incorporate feedback from design review

|

1.

Research up-cycling with plastic. List two

websites that helped you think about products that you could create and the

process involved.

2.

Start brainstorming what your product will be,

and how you will make it.

a.

Materials?

Friday, March 24, 2017

March 24th- GRNG 101's

Algae is doing well. T-connectors giving uneven air pressure.

Dr. T researched buying additional gas manifolds.

Materials Group worked on chair design using recycled materials, with water bottles serving as legs. I suggested that water bottles should be filled for greater compressive strength.

Bicycle group tested generator- put out 12-13.5 volts when pedaling fast. Was able to use to charge a cellphone.

Aquaponics team studied water supply system.

Thursday, March 23, 2017

March 22nd- Auger for Fish Feeder

Spencer reported problems with the fish feeder clogging. Found an auger-based design online, and 3D-printed auger at MIT Edgerton Lab:

Friday, March 10, 2017

March 10th- GRNG 201's

Eric and Maggie added siding to the main tank:

Spencer was absent, so I worked on running Neopixels with the Arduino:

/* Neopixel Ring- Single Red LED spins around circle; can be powered by +5V pin.

//if lots of LEDs need to be turned on at the same time, you can use an L298N Motor driver as a 5V supply( connect GND to GND, Vin(+12) to +12V, 5V out to

Neopixels power lead[red]

To avoid damage to Neopixels add a 500 ohm resistor into data line and 1000 uF capacitor across 5V supply. See Adafruit Neopixel Uberguide Best Practices

https://learn.adafruit.com/adafruit-neopixel-uberguide/best-practices

*/

#include <Adafruit_NeoPixel.h>

#include <avr/power.h>

#define PIN

6 //data pin #

// How many NeoPixels are attached to the Arduino?

#define NUMPIXELS

24

Adafruit_NeoPixel pixels = Adafruit_NeoPixel(NUMPIXELS, PIN,

NEO_GRB + NEO_KHZ800);

void setup() {

pixels.begin(); //

This initializes the NeoPixel library.

}

void loop() {

// For a set of

NeoPixels the first NeoPixel is 0, second is 1, all the way up to the count of

pixels minus one.

for (int i = 0; i

< NUMPIXELS; i++) {

// pixels.Color

takes RGB values, from 0,0,0 up to 255,255,255

pixels.setPixelColor(i, pixels.Color(50, 0, 0)); // Moderately bright

green color.

pixels.show(); // This

sends the updated pixel color to the hardware.

delay(10);

pixels.setPixelColor(i, pixels.Color(0, 0, 0)); // Moderately bright

green color.

delay(10);

}

}

----------------------------------------------------------------------------------------------------

Stepper Motor:

M1: Red/Green M2:Yellow/Blue

----------------------------------------------------------------------------------------------------

Stepper Motor:

M1: Red/Green M2:Yellow/Blue

/*

Simpler Stepper

Motor Control using Adafruit Motor Shiled V2

Wiring: Power

Arduino Uno with 12V power Supply

Attach Adafruit V2

Motor Shield

Leave Vin Power

jumper in place

Attach stepper motor

wires to M1(Red/Green) and M2(Yellow/Blue)

*/

#include <Wire.h>

#include <Adafruit_MotorShield.h>

#include "utility/Adafruit_MS_PWMServoDriver.h"

int dollops = 3;// set number of food dollops per feeding

// Create the motor shield object with the default I2C

address

Adafruit_MotorShield AFMS = Adafruit_MotorShield();

// Connect a stepper motor with 200 steps per revolution

(1.8 degree)

// to motor port #1 (M1 and M2)

Adafruit_StepperMotor *myMotor = AFMS.getStepper(200, 1);

void setup() {

AFMS.begin(); // create with the default frequency 1.6KHz

myMotor->setSpeed(10); // 10

rpm

}

void loop() {

dispenseFood(dollops);//dispense food

delay(60000); //

wait one minute-- change to desired interval

}

void dispenseFood( dollops)

{

for ( int i = 0; i

< dollops; i++) {

myMotor->step(100, FORWARD, DOUBLE);//turn halfway around

delay(1000);

myMotor->step(100, BACKWARD, DOUBLE);//turn back

delay(1000);

}

}

Subscribe to:

Comments (Atom)